|

|

Petroleum and Chemical Consulting and Modeling for Enhanced Oil Recovery |

|---|---|---|

Houston, TX - Phone: (281) 564 - 8851 |

||

Benefits of Steam and Gas Coinjection |

||

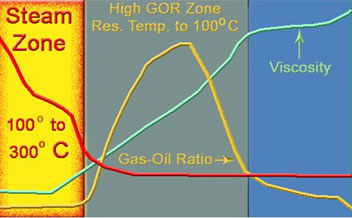

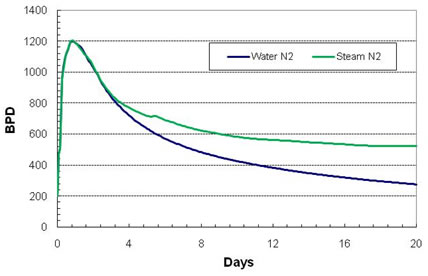

It is important to recognize that a gas moves much faster than steam because steam can only advance when the reservoir is heated to steam temperature. This means that gas has two effects. The first is to reduce the viscosity in the oil ahead of the steam front. This is shown the first figure below, where a region of higher GOR precedes the steam front in the simplified schematic of a high-pressure steam-gas process. The GOR is high when the temperature is low. Then the GOR decreases as the oil is heated until the steam zone is entered where there is little gas in the oil. The oil’s viscosity is kept low then by the high temperature. Any gas added to the steam has this effect on oil viscosity. So addition of nitrogen, CO2 of reservoir gas to steam all can accelerate oil production. This is shown in the next figure where adding nitrogen to both steam and water results in the same initial production.

|

||

Schematic of Important Zones in Steam-Gas Process |

||

|

||

Result of Adding 5% N2 to Steam and Water for a 500 cp Oil at 600 psig |

||

|

||

|

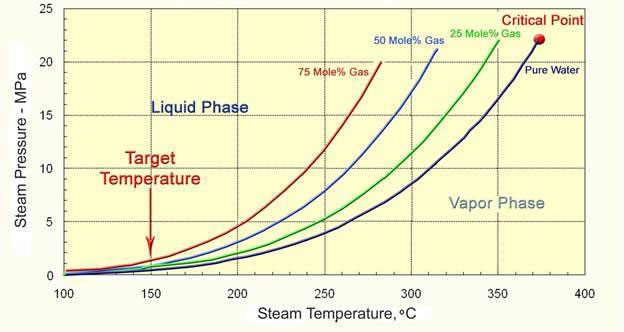

The second effect of gas is shown in the third figure of the series. This figure shows that gas reduces the partial pressure of water and therefore it reduces the temperature at which steam condenses and evaporates. This means that the steam has to heat the rock less to heat oil and the steam moves into the reservoir faster. Now, if the pressure is low, the temperature of the steam is also low. The three figures suggest that gas has less of a beneficial effect at low pressure than at high pressure where gas can modify the temperature of the steam as well as dissolve in the oil to reduce its viscosity. |

|

Steam Pressure vs. Temperature |

||

|

||

|

The result of these two effects is faster production of more oil as shown in the figure above. |

|

| For Questions Please Contact Us At MK Tech Solutions, Inc. - Houston, TX - Phone: (281) 564 - 8851 ASKMKTS@MKTechSolutions.com |

|---|